EST4 system test and commissioning procedures

The EST4 system is a state-of-the-art solution that offers advanced functionalities and features for effective testing and commissioning. In order to ensure the smooth operation of this system, it is vital to understand its key components and functionality. This article will provide a comprehensive guide to the EST4 system test and commissioning procedures, encompassing everything from pre-test preparations to troubleshooting common issues and post-commissioning maintenance.

Understanding the EST4 System

The EST4 system is a powerful tool used for testing and commissioning various electrical installations. It comprises several key components that work together seamlessly to provide accurate results and ensure the safety of the entire process.

When it comes to electrical installations, safety is of utmost importance. The EST4 system is designed with this in mind, incorporating features and functionalities that guarantee the reliability and efficiency of the testing and commissioning process.

Key Components of the EST4 System

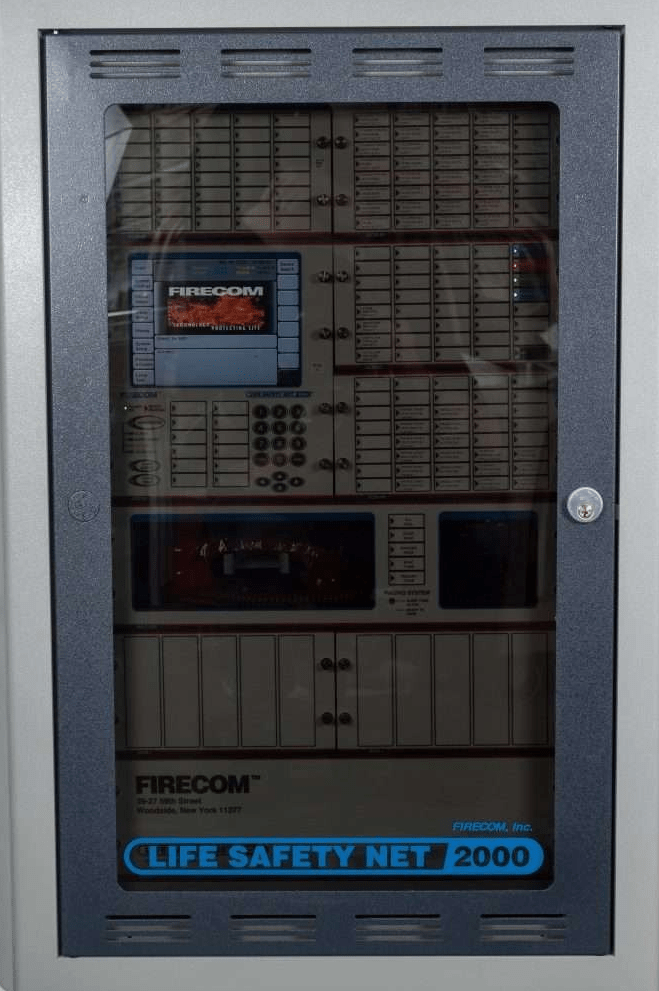

The EST4 system consists of:

- Control unit: the central hub that manages the testing process and communicates with other components.

- Testing probes and sensors: essential tools for establishing connections and collecting data during the tests.

- Display unit: the user interface where test results and system information are presented.

- Software interface: the program that allows users to control and monitor the testing process.

Each component plays a vital role in ensuring the effectiveness and accuracy of the EST4 system. The control unit acts as the brain of the system, coordinating the different operations and facilitating communication between the various components. The testing probes and sensors, on the other hand, enable the system to gather data and establish connections with the electrical installations being tested.

Meanwhile, the display unit serves as the interface through which users can access and interpret the test results and system information. It provides a clear and user-friendly platform, allowing for easy navigation and understanding of the data presented. Lastly, the software interface acts as the control center, enabling users to monitor and control the testing process with precision and efficiency.

Functionality and Features of the EST4 System

The EST4 system offers a wide range of functionalities and features, making it a versatile tool for testing and commissioning.

One of the notable features of the EST4 system is its wide compatibility. It supports various types of electrical installations, allowing for comprehensive testing. Whether it’s a residential, commercial, or industrial setting, the EST4 system can adapt to the specific requirements of the installation, ensuring accurate and reliable results.

In addition to its compatibility, the EST4 system also boasts advanced data analysis capabilities. The software interface provides detailed reports and analysis, aiding in the identification of potential issues. This feature allows users to pinpoint any anomalies or irregularities in the electrical installations, enabling them to take necessary actions to rectify the problems before they escalate.

Real-time monitoring is another significant functionality of the EST4 system. It allows users to monitor the testing process as it happens, providing instant feedback and alerts in case of any abnormalities. This real-time monitoring capability ensures prompt detection of any issues, minimizing the risk of accidents or malfunctions.

Furthermore, the EST4 system is designed with an intuitive user interface. The display unit offers a user-friendly platform, simplifying the operation of the system. Even users with minimal technical knowledge can navigate through the interface effortlessly, making the testing and commissioning process more accessible and efficient.

In conclusion, the EST4 system is a comprehensive and reliable tool for testing and commissioning electrical installations. With its key components working harmoniously and its wide range of functionalities and features, the EST4 system ensures accurate results, enhances safety, and simplifies the testing process for users.

Pre-Test Procedures for the EST4 System

Prior to conducting tests using the EST4 system, it is essential to follow specific pre-test procedures to guarantee both safety and accuracy.

Testing procedures can be complex and require careful attention to detail. By following the pre-test procedures outlined below, you can ensure a smooth and successful testing process.

Safety Measures and Precautions

Safety should be the utmost priority during testing procedures. To ensure a safe testing environment, it is crucial to implement the following safety measures:

- Disconnect all electrical power sources before connecting the EST4 system.

- Wear personal protective equipment (PPE) such as gloves and safety glasses.

- Ensure proper grounding of the system and test setup to prevent electric shock hazards.

- Clear the testing area of any potential hazards or obstacles that could interfere with the testing process.

- Establish clear communication channels and emergency protocols in case of any unforeseen incidents.

By adhering to these safety measures, you can minimize the risk of accidents and create a secure testing environment for all involved.

Necessary Equipment and Tools

Before starting the test, gather all the necessary equipment and tools to ensure a smooth testing process:

- EST4 system components: control unit, testing probes, sensors, and the display unit.

- Testing cables and connectors.

- Hand tools for establishing connections and securing the test setup.

- Calibration equipment to ensure accurate readings and measurements.

- Backup power sources in case of power outages or system failures.

Having all the required equipment and tools readily available will save time and prevent any unnecessary delays during the testing process.

Additionally, it is important to ensure that all equipment and tools are in good working condition. Perform regular maintenance and inspections to identify any potential issues beforehand.

Furthermore, it is recommended to have a designated area or workstation specifically dedicated to the EST4 system and its testing procedures. This will help maintain organization and prevent any confusion or misplacement of equipment.

Lastly, it is advisable to have a backup plan in case of any unforeseen circumstances or technical difficulties. This can include having spare parts or alternative testing methods available to ensure the continuity of the testing process.

Step-by-Step Guide to EST4 System Testing

Conducting tests using the EST4 system involves a systematic approach to ensure accurate results and efficient testing. The following step-by-step guide outlines the testing process:

Initial Setup for Testing

Before starting the actual test, it is crucial to perform the initial setup, including:

- Connecting the testing cables and probes to the appropriate test points.

- Verifying the connections and ensuring they are secure to prevent interruptions during the test.

- Configuring the system software to align with the specific test requirements and parameters.

Running the Test and Interpreting Results

Once the system is properly set up, it’s time to run the test and interpret the results effectively. Follow these steps:

- Initiate the test using the control unit or software interface.

- Monitor the testing process in real-time, ensuring that all measurements are within acceptable limits.

- Record the test data accurately for future analysis and troubleshooting purposes.

- Interpret the test results based on the system’s software analysis and diagnostic tools.

Commissioning Procedures for the EST4 System

After the successful completion of the testing process, the commissioning phase is essential to ensure the system is fully functional and ready for operation.

During the commissioning phase, a series of procedures are followed to verify the system’s capabilities and ensure it meets all necessary requirements. This phase is crucial in guaranteeing the system’s optimal performance and reliability.

Pre-Commissioning Checklist

Prior to commissioning the EST4 system, it is essential to perform a pre-commissioning checklist to verify that all necessary requirements are met:

- Ensure all components and connections are intact and functioning correctly. This includes checking the wiring, circuit boards, and any external devices that are part of the system.

- Verify that the system software is up-to-date and free from any errors or bugs. This ensures that the system operates smoothly and efficiently.

- Perform a last-minute check of safety measures to guarantee a safe commissioning process. This involves inspecting safety features such as emergency shut-off switches, fire suppression systems, and any other safety mechanisms.

By completing this checklist, technicians can identify any potential issues or discrepancies that may hinder the commissioning process. Addressing these concerns beforehand ensures a smoother and more successful commissioning phase.

Detailed Commissioning Process

The commissioning process involves several intricacies that must be followed to ensure the system functions optimally:

- Power up the system and verify that all components are operational. This includes checking the power supply, control panels, and any other electrical components.

- Calibrate all testing probes and sensors to ensure accurate readings. This step is crucial in guaranteeing the system’s ability to detect and respond to various environmental conditions.

- Conduct a series of test runs to validate the system’s performance and consistency. This includes simulating different scenarios and monitoring the system’s response to ensure it meets the desired specifications.

- Create comprehensive commissioning reports documenting every step and result of the process. These reports serve as a reference for future maintenance and troubleshooting, providing a detailed overview of the system’s commissioning history.

Throughout the commissioning process, technicians closely monitor the system’s performance, making adjustments and fine-tuning as necessary. This iterative approach ensures that any issues or limitations are addressed, resulting in a fully functional and reliable EST4 system.

Troubleshooting Common Issues in EST4 System

Despite the reliability of the EST4 system, issues may arise during testing or commissioning. Identifying and resolving these issues promptly is crucial to maintain the system’s efficiency.

When troubleshooting the EST4 system, it is important to be aware of the common problems that may occur. By understanding these issues, you can effectively address them and ensure the system operates smoothly.

Identifying Common Problems

Efficient troubleshooting begins with the identification of common problems that may occur during testing or commissioning:

- Intermittent connectivity issues between the system components.

- Inaccurate readings or discrepancies between test results and expected parameters.

- Software glitches or compatibility issues that hinder the proper functioning of the system.

Intermittent connectivity issues can be frustrating and may disrupt the overall performance of the EST4 system. These issues can be caused by loose connections, damaged cables, or interference from other electronic devices. It is important to ensure all connections are secure and cables are undamaged. Additionally, minimizing the proximity of other electronic devices can help reduce interference.

Inaccurate readings or discrepancies between test results and expected parameters can lead to confusion and misinterpretation of data. Regular calibration of testing probes and sensors is essential to maintain accuracy. By calibrating these components at regular intervals, you can ensure that the readings obtained from the EST4 system are reliable and consistent.

Software glitches or compatibility issues can sometimes hinder the proper functioning of the EST4 system. To address these issues, it is recommended to update the system software to the latest version. Software updates often include bug fixes and improvements that can resolve any software-related issues. It is important to follow the manufacturer’s instructions when updating the software to ensure a smooth and successful update process.

Effective Solutions and Fixes

The following solutions can help in resolving common issues efficiently:

- Ensure all connections are secure, and cables are undamaged.

- Calibrate testing probes and sensors regularly to maintain accuracy.

- Update the system software to the latest version to resolve any software-related issues.

- Consult the system’s user manual and contact technical support if necessary to resolve complex issues.

Regularly checking the connections and cables of the EST4 system is a simple yet effective solution to prevent connectivity issues. By ensuring that all connections are secure and cables are undamaged, you can minimize the risk of intermittent connectivity problems.

Calibrating testing probes and sensors regularly is crucial to maintain the accuracy of the EST4 system. Over time, these components may drift and produce inaccurate readings. By following the manufacturer’s guidelines for calibration and performing this task at regular intervals, you can ensure that the system provides reliable and precise data.

Updating the system software to the latest version is an important step in resolving software-related issues. Manufacturers often release software updates to address bugs, improve compatibility, and introduce new features. By keeping the system software up to date, you can benefit from these enhancements and ensure the smooth operation of the EST4 system.

In complex situations where common troubleshooting steps may not be sufficient, it is advisable to consult the system’s user manual and contact technical support. The user manual provides detailed information about the system’s functionalities and troubleshooting procedures. Technical support can offer expert guidance and assistance in resolving complex issues that may arise during testing or commissioning.

By following these effective solutions and fixes, you can troubleshoot common issues in the EST4 system efficiently. Timely identification and resolution of problems will help maintain the system’s efficiency and ensure its reliable performance in various applications.

Maintaining the EST4 System Post-Commissioning

Regular maintenance of the EST4 system is essential for long-term performance and reliability.

Routine Maintenance Guidelines

To ensure the system functions optimally, adhere to these routine maintenance guidelines:

- Periodically inspect all connections and clean the system components to prevent dust or debris buildup.

- Test the system at regular intervals to identify any potential issues before they become critical.

- Keep the system software up-to-date to benefit from the latest features and bug fixes.

Long-Term System Care and Management

For extended system lifespan and optimal performance, consider the following long-term care strategies:

- Store the system components in a controlled environment when not in use.

- Keep a detailed record of all tests, repairs, and maintenance activities for future reference.

- Train personnel regularly to ensure they are up-to-date with the system’s operation and maintenance.

In conclusion, effective testing and commissioning procedures are crucial for the successful operation of the EST4 system. By understanding its key components, following pre-test procedures, conducting systematic testing and commissioning, troubleshooting common issues, and implementing routine maintenance, you can ensure that the system performs optimally, delivering accurate results and contributing to a safe environment for electrical installations.